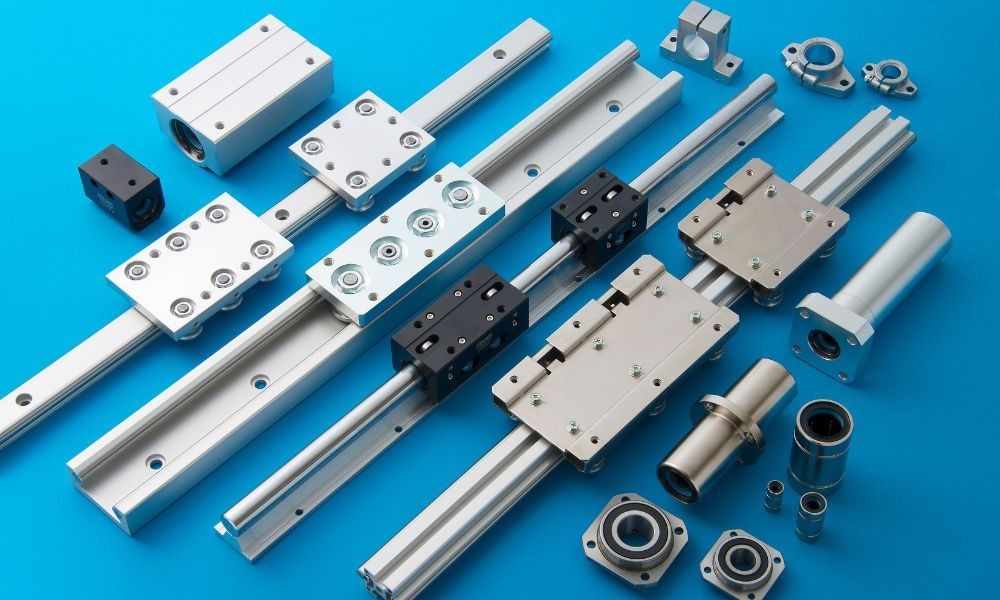

In today’s fast-paced industrial world, efficiency and durability are essential. One crucial component enabling machines to run seamlessly is NRS Bearings. Designed with precision and engineered for strength, NRS Bearings are necessary for various applications, ensuring smoother operations and significantly extending the lifespan of machinery. Here’s a closer look at why NRS Bearings are revolutionizing the industrial world and how they provide unmatched reliability.

Why NRS Bearings Stand Out in Performance and Durability

NRS Bearings are crafted with specialized materials and innovative design techniques that differentiate them from traditional bearings. These high-quality components are optimized for maximum load-bearing capacity and rotational speed, making them an ideal solution for heavy-duty applications where consistency is critical. Industrial sectors ranging from automotive to aerospace have increasingly turned to NRS Bearings for their impressive wear resistance and heat management capabilities.

Key features that elevate NRS Bearings include:

- Enhanced Durability: Engineered to withstand high-stress conditions and extreme temperatures, NRS Bearings extend machinery’s operational lifespan, reducing the need for frequent replacements.

- High Load-Bearing Efficiency: NRS Bearings are designed to support significant loads without compromising performance, making them suitable for high-demand environments.

- Superior Precision: With advanced manufacturing processes, NRS Bearings maintain precise alignment, minimizing friction and reducing vibration, which ultimately leads to smoother operation.

The Role of NRS Bearings in Reducing Maintenance Costs

Reduced maintenance frequency is a priority when it comes to industrial machinery. NRS Bearings play an integral role by minimizing the chances of mechanical breakdowns. This reliability means less downtime, saving both time and costs associated with repairs. Businesses aiming to enhance their efficiency have embraced NRS Bearings as a sustainable, cost-effective choice.

In addition, NRS Bearings require less lubrication than conventional bearings, further contributing to operational savings. Over time, this translates to a reduction in maintenance labor and expenses, solidifying their position as a cost-efficient component in many industrial applications.

Applications of NRS Bearings Across Industries

Industries such as manufacturing, automotive, and logistics have witnessed significant improvements by integrating NRS Bearings into their operations. Thanks to their compact yet robust design, these bearings can be applied in various settings, providing versatility for many applications. From conveyor belts in warehouses to high-precision tools in manufacturing, NRS Bearings are versatile enough to suit a wide array of machinery and equipment.

Invest in Quality with NRS Bearings (ตลับลูกปืน LM Guide NRS, which is the term in Thai)

For companies seeking reliable, durable components that offer long-term performance, NRS Bearings prove to be a top choice. Their resilience, efficiency, and adaptability make them an indispensable part of today’s industrial machinery. By investing in quality bearings like the NRS series, companies can ensure smoother operations, reduced maintenance costs, and longer-lasting equipment life.

Related posts

Categories

Recent Posts

Advertisement