Wedge wire screens are widely used in various industries for their excellent filtration capabilities. These screens consist of wedge-shaped wires that are welded onto support rods to create a precise and durable filter medium. Wedge wire screen manufacturers specialize in producing these high-quality screens for different applications, such as water treatment, food processing, mining, and oil and gas.

The demand for wedge wire screens has been increasing rapidly due to their superior filtration performance compared to traditional filter media such as mesh or perforated plates. Additionally, the flexibility and customization options offered by wedge wire screen manufacturers make them an ideal choice for industries with specific filtering needs.

Manufacturing process: How are they made?

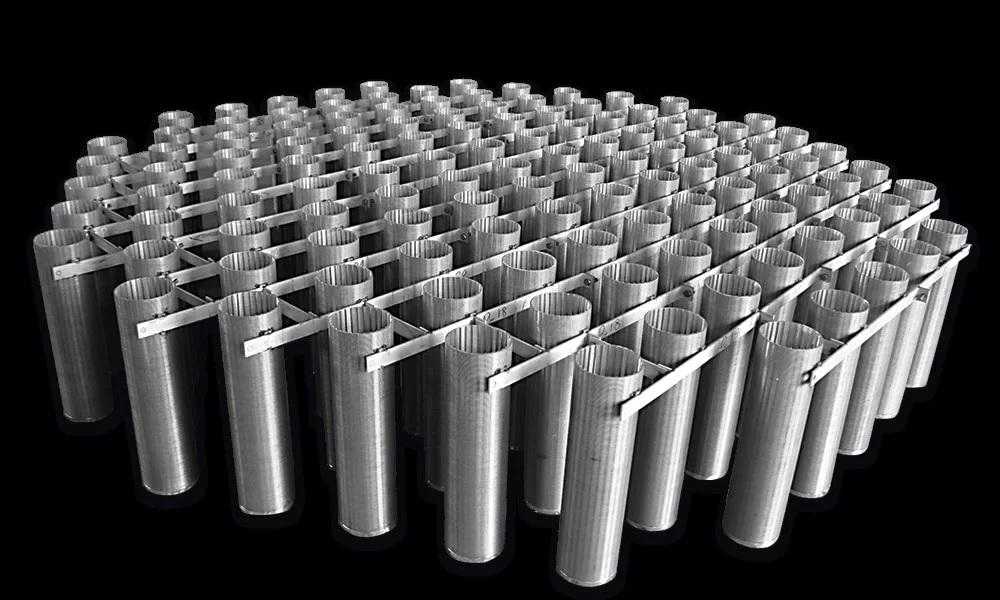

Wedge wire screens are used in many industrial applications such as filtration, water treatment, and separation of solids from liquids. The manufacturing process of wedge wire screens involves several steps. First, the raw materials such as stainless-steel wires are sourced and then straightened to the desired length. Then, these wires are welded onto support rods at specific intervals to form a V-shaped profile.

After welding, the wedge wire screen is put through a series of processes including cutting, shaping and polishing to achieve its final form. The finished product is then inspected for quality before being packaged and shipped out to customers.

Overall, the manufacturing process of wedge wire screens requires precision and attention to detail at every step to ensure that they meet industry standards and function effectively in their intended applications.

How to choose manufacturers

When it comes to choosing wedge wire screen manufacturers, there are a few key factors that you should consider. The first is the quality of the products they offer. Look for manufacturers that use high-quality materials and employ rigorous testing processes to ensure their products meet industry standards. It’s also important to consider the range of products they offer, as well as their ability to customize screens to your exact specifications.

Another important factor when choosing wedge wire screen manufacturers is their reputation in the industry. Search for companies with a long history of producing high-quality screens and serving satisfied customers. You can also check online reviews and ratings from other customers or industry experts to get an idea of how each manufacturer performs.

Finally, don’t forget about customer service when selecting a wedge wire screen manufacturer. Choose a company that is responsive to your needs and provides excellent support throughout the entire process, from initial design through installation and maintenance. By considering these factors carefully, you’ll be able to select a reliable manufacturer that can deliver top-notch wedge wire screens for your specific needs.

Wedge wire screen manufacturers provide tailored solutions

When it comes to sourcing wedge wire screens, it is beneficial to work with manufacturers that offer flexibility and customization options. These manufacturers understand the diverse needs of their customers and strive to provide tailored solutions. Here are some key points highlighting the flexibility and customization options offered by wedge wire screen manufacturers:

- Customized Sizes: Manufacturers of wedge wire screens can produce screens in a wide range of sizes to meet specific requirements. They can customize the length, width, and diameter of the screens to fit different equipment or filtration systems. This ensures a perfect fit and optimal performance.

- Slot Openings and Profiles: The slot openings and profiles of wedge wire screens can be customized based on the application and desired filtration or separation requirements. Manufacturers can offer a variety of slot sizes, shapes, and configurations to accommodate different particle sizes and fluid flow rates.

- Material Selection: Wedge wire screen manufacturers typically offer a selection of materials to suit various operating conditions. They can provide screens in different grades of stainless steel or other corrosion-resistant alloys, allowing customers to choose the most suitable material for their specific application, such as high-temperature environments or corrosive fluids.

Categories

Recent Posts

Advertisement